Role of ventilation system in factory

Ventilation system is an important system in the factory, which functions to provide fresh air, remove polluted air, create a safe and comfortable working environment for workers.

Harm of poor ventilation system

If the ventilation system in the factory does not work well, it will lead to the accumulation of dust in the factory over time. At the same time, the human respiratory process also increases the concentration of CO2 gas, reducing O2 a lot. Together with the humidity in the factory, mold and bacteria grow. Harmful emissions such as formaldehyde, viruses, mold, ... accumulate more and more, causing great harm to human health. The increase in dust in the factory will be a risk of causing dangerous diseases to human health and life. Combined with the lack of oxygen, it will make it difficult for humans to breathe. Therefore, timely intervention measures need to be used.

Factors to consider when designing a ventilation system

In the design of a ventilation system, many factors must be considered:

- Source of dust and smoke: The source of dust and smoke in the factory can come from many different sources, such as production processes, machinery, equipment, etc. The dispersion ability of dust and smoke in the factory also needs to be considered.

- Factory layout: The layout of the factory has a great influence on the airflow in the factory. Production areas, working areas, storage areas, etc. need to be arranged properly to ensure good air circulation.

- Current air flow models: Current air flow models need to be studied to identify hot spots, areas with high risk of pollution.

- Future process changes: If there are future process changes, the impact of these changes on the ventilation system needs to be considered.

Steps to design a ventilation system

Ventilation Mapping implements the design of a ventilation system in the following 5 steps:

- On-site consultation: Ventilation Mapping will conduct on-site consultation to better understand the challenges and goals of customers.

- Data collection: Ventilation Mapping will collect data on the source of dust and smoke, factory layout, current air flow models, etc.

- Modeling: Ventilation Mapping will build a 3D model for the customer's facility, including factors affecting airflow.

- System design: Ventilation Mapping will design the optimal ventilation system based on the results of modeling and customer requirements.

- Final evaluation and analysis: Ventilation Mapping will evaluate and analyze the ventilation system after it has been implemented to ensure the system is operating effectively.

Benefits of an effective ventilation system

An effective ventilation system brings many benefits to the factory, including:

- Ensuring a safe and comfortable working environment for workers.

- Reducing air pollution, preventing respiratory diseases.

- Increase labor productivity.

- Save costs.

Therefore, the design and installation of an effective ventilation system is extremely important for factories.

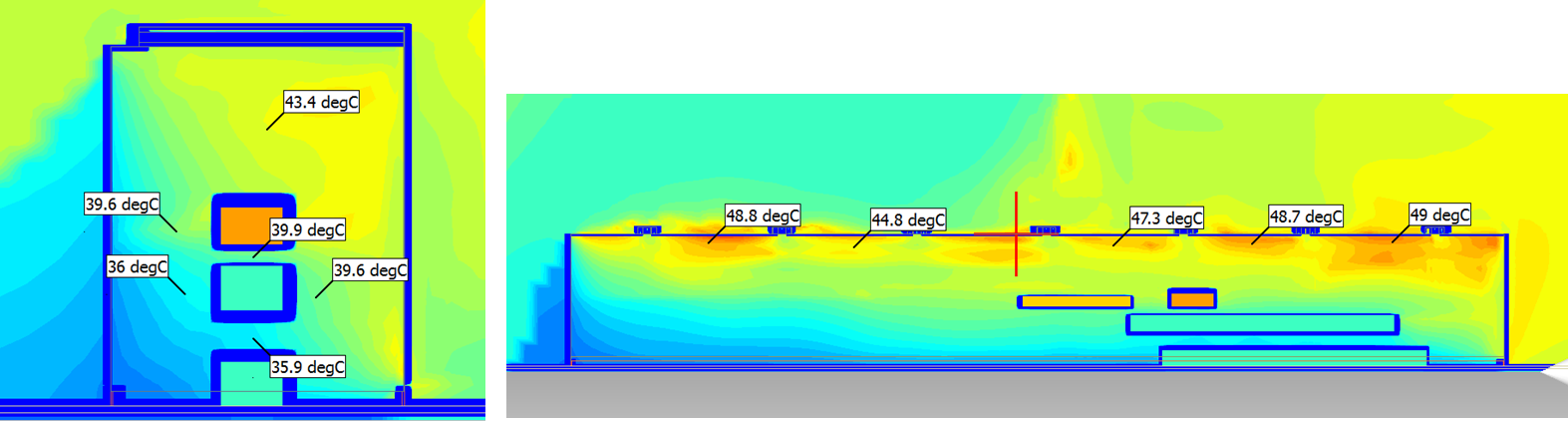

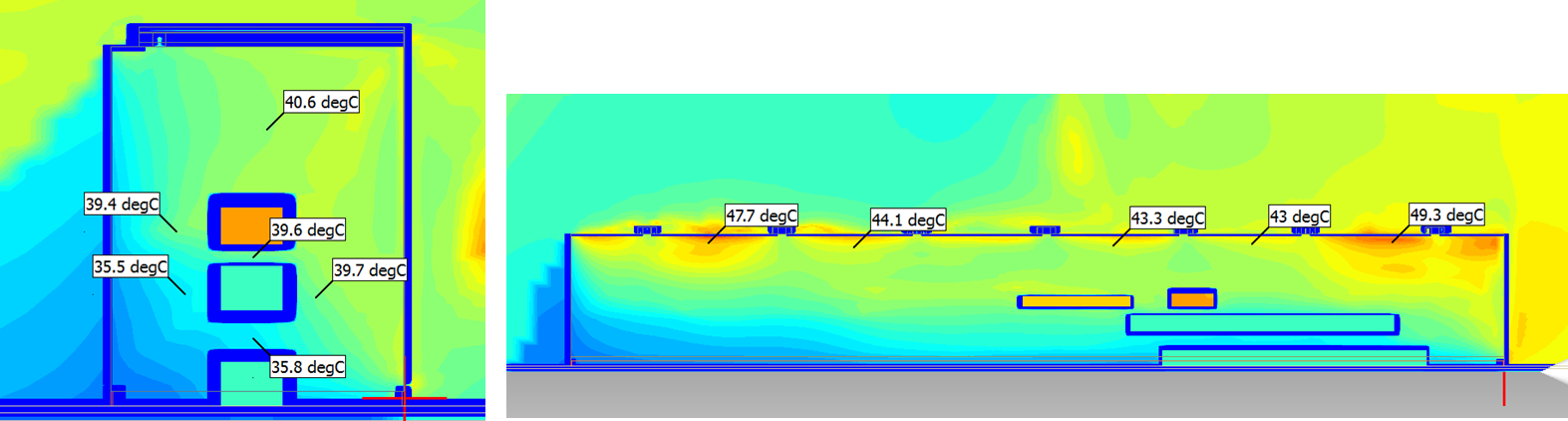

The air temperature inside the factory

| Before |  |

| After |  |

Air movement inside the factory

| Before |  |

| After |  |

---------------------------------------------